Special steel is precision-forged to form a drill housing.

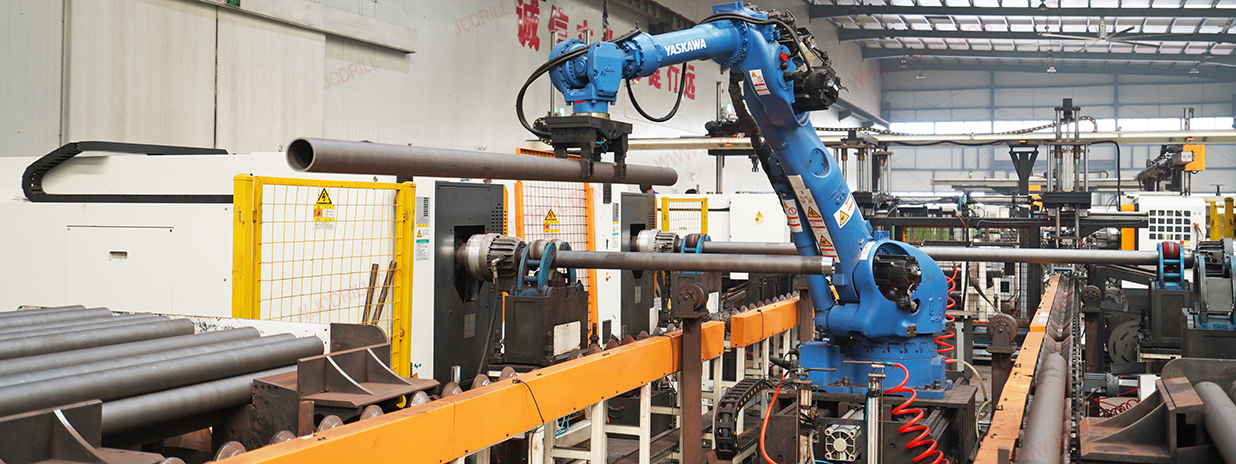

We have 17 sets of CNC machining centers including3m gantry machining center,6163 horizontal boringmachine,400 sets CNC lathes,39 sets CNC millingmachines, 15 sets deep hole internal grinding machines,31 sets universal cylindrical grinding, and 2 sets 61125Spark-brand machines.

Alloys use well-known domestic enterprises to support, to ensure that in rock drilling operations, the comprehensive wear resistance of products higher than industry standards. When the housing and alloy combine, we use one hole, one tooth test, to ensure that the product in use, do not appear teeth, shedding phenomenon.

With advantage painting equipment,all our drilling tools with strict surface cleaning,preparation, finished painting, and refinishing,high quality paint give drilling tools measure of protection against moisture and oxidation during transportation and working.

We can fulfill customer' sspecial requirement for smelting,forging the suitablespecial steel, and steel bar surface mechanical peeling bycenterless lathe,inspecting by ultrasonic flaw detectionto ensure the quality of raw material of steel.

We can not only forge large size workpieces but also can process any steel products bynormalizing, tempering, carburizing, oil quenching and salt quenching, surface treatment,blackening and nitrogen treatment. We have rich experience and accurate control on heattreatment, cold machining and surface treatment, so that the workpieces can meet thebest quality in using.

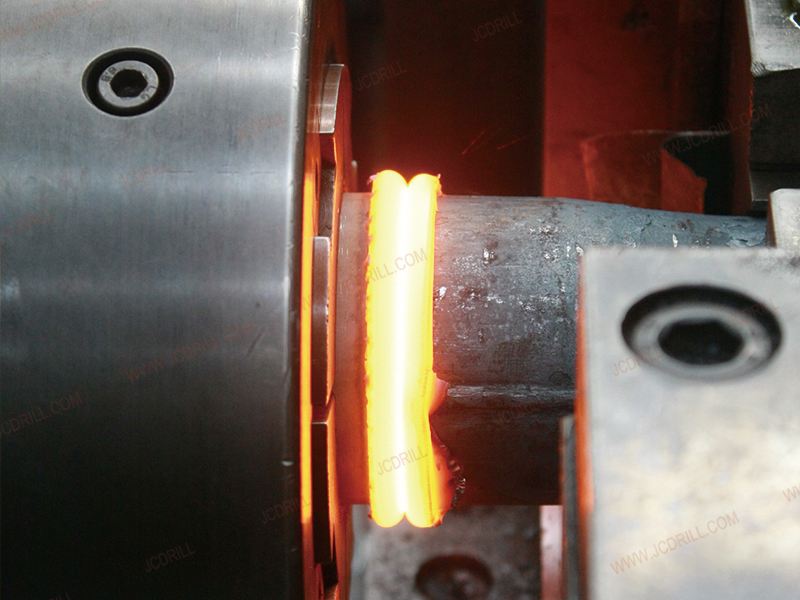

To ensure the quality of drill pipe welding, by the con-tinuous friction welding technology andcomputers to detect welding parameters.Using welding heat and top deformation,the weld structure is subjected to second-ary tempering treatment with solid high fre-quency quenching equipment. Make the weldingplace beautiful and tidy, and improve thereplacement of drill pipe.

We adopt high-strength and convenient packaging, which not only ensures the protection of drilling tools during transportation, but also facilitates the transportation and handling of users. All product packaging can be customized according to user requirements.