Introduction of Tricone bits

The TCI Tricone bits drilling for medium to hard rock formation.

The medium formation TCI tricone bits features aggressive chisel tungsten carbide inserts on the heel rows and inner rows. This design provides a fast drilling rate and added cutting structure durability in medium to medium hard formations. The HSN rubber O-ring provides adequate sealing for bearing durability.

The hard formation TCI tricone bits can be used to drill hard and abrasive formation. Wear resistance tungsten carbide inserts are used in the outer rows to prevent loss of bit gauge. Maximum numbers of hemispherical shaped inserts are used in all rows to provide cutter durability and long life.

Milled tooth Tricone Rock Drill Bits:

The milled tooth (steel tooth) tricone bits drilling for soft to medium rock formation.

The soft formation milled tooth tricone bits are used to drill low compressive strength, soft formation. Long projection tooth lengths are used on high offset cones to provide the greatest penetrations rates possible. Wear resistance hard facing is used to control tooth wear. On the softest bit types this hard facing completely covers the bit teeth.

The medium formation milled tooth tricone bits are used to drill high compressive strength, medium rock formation. Shoot projection teeth with reduced crest length are used in this series of bit designs. Durable hard facing is applied to reduce tooth wear.

Characteristics

Medium soft with low compressive strength and harder abrasive stringers,such as hard shale,hard gypsolyte,soft limestone,sandstone and dolomite with stringers,etc.

Offset crested scoop compacts in inner row,wedge compacts in outer row,imequable spaced compacts arrangement,and a row of trimmers is added between gage row and heel row

Guidance of Tricone Bit Choice

| IADC | WOB(KN/mm) | RPM(r/min) | APPLICABLE FORMATIONS |

| 114/116/117 | 0.3~0.75 | 180~60 | Very soft formations with low compressive strength and high drillability, such as clay, mudstone, chalk, etc. |

| 124/126/127 | 0.3~0.85 | 180~60 | Soft formations with low compressive strength and high drillability, such as mudstone, gypsum, salt, soft limestone, etc. |

| 134/135/136/137 | 0.3~0.95 | 150~60 | Soft to medium formations with low compressive strength and high drillability, such as medium soft shale, hard gypsum, medium soft limestone, medium soft sandstone, soft formation with harder interbed, etc. |

| 214/215/216/217 | 0.35~0.95 | 150~60 | Medium formations with high compress strength, such as medium soft shale, hard gypsum , medium soft limestone, medium soft sandstone, soft formation with harder interbed, etc. |

| 227 | 0.35~0.95 | 150~50 | Medium hard formations with high compressive strength, such as abrasive shale, limestone, sandstone, dolomite, hard gypsum, marble,etc |

| Note: The upper limits of WOB and RPM in above table should not be used simultaneously. | |||

Guidance of tricone Bits ChoiceTricone Bits Tooth Type

Bits Size

| Bit Size | API REG PIN | Torque | Weight | |

| Inch | mm | Inch | KN.M | Kgs |

| 3 3/8 | 85.7 | 2 3/8 | 4.1-4.7 | 4.0-6.0 |

| 3 1/2 | 88.9 | 4.2-6.2 | ||

| 3 7/8 | 98.4 | 4.8-6.8 | ||

| 4 1/4 | 108 | 5.0-7.5 | ||

| 4 1/2 | 114.3 | 5.4-8.0 | ||

| 4 5/8 | 117.5 | 2 7/8 | 6.1-7.5 | 7.5-8.0 |

| 4 3/4 | 120.7 | 7.5-8.0 | ||

| 5 1/8 | 130.2 | 3 1/2 | 9.5-12.2 | 10.3-11.5 |

| 5 1/4 | 133.4 | 10.7-12.0 | ||

| 5 5/8 | 142.9 | 12.6-13.5 | ||

| 5 7/8 | 149.2 | 13.2-13.5 | ||

| 6 | 152.4 | 13.6-14.5 | ||

| 6 1/8 | 155.6 | 14.0-15.0 | ||

| 6 1/4 | 158.8 | 14.4-18.0 | ||

| 6 1/2 | 165.1 | 14.5-20.0 | ||

| 6 3/4 | 171.5 | 20.0-22.0 | ||

| 7 1/2 | 190.5 | 4 1/2 | 16.3-21.7 | 28.0-32.0 |

| 7 5/8 | 193.7 | 32.3-34.0 | ||

| 7 7/8 | 200 | 33.2-35.0 | ||

| 8 3/8 | 212.7 | 38.5-41.5 | ||

| 8 1/2 | 215.9 | 39.0-42.0 | ||

| 8 5/8 | 219.1 | 40.5-42.5 | ||

| 8 3/4 | 222.3 | 40.8-43.0 | ||

| 9 1/2 | 241.3 | 6 5/8 | 38-43.4 | 61.5-64.0 |

| 9 5/8 | 244.5 | 61.8-65.0 | ||

| 9 7/8 | 250.8 | 62.0-67.0 | ||

| 10 | 254 | 68.0-75.0 | ||

| 10 1/2 | 266.7 | 72.0-80.0 | ||

| 10 5/8 | 269.9 | 72.0-80.0 | ||

| 11 1/2 | 292.1 | 79.0-90.0 | ||

| 11 5/8 | 295.3 | 79.0-90.0 | ||

| 12 1/4 | 311.2 | 95.0-102. | ||

| 12 3/8 | 314.3 | 95.0-102.2 | ||

| 12 1/2 | 317.5 | 96.0-103.0 | ||

| 13 1/2 | 342.9 | 105.0-134.0 | ||

| 13 5/8 | 346.1 | 108.0-137.0 | ||

| 14 3/4 | 374.7 | 7 5/8 | 46.1-54.2 | 140.0-160.0 |

| 15 | 381 | 145.0-165.0 | ||

| 15 1/2 | 393.7 | 160.0-180.0 | ||

| 16 | 406.4 | 200.0-220.0 | ||

| 17 1/2 | 444.5 | 260.0-280.0 | ||

| 26 | 660.4 | 725.0-780.0 | ||

Production Process

Introduction

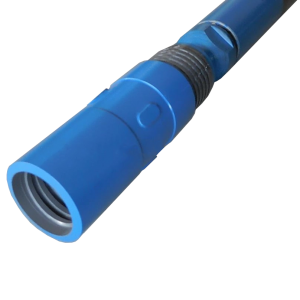

5 1/2 Inch Water Well Roller Cone Bit 114mm Steel Tooth Tricone Bit

The tricone drill bit is the most popular drilling bit in the world,it can be widely used for Oil&Gas Drilling,Mining,Water Well,Geological Exploration areas.Our tricone bit divideds into metal sealed drill bit and rubber sealed bit.

1. The C-Center jet can avoid the formation of a ball in the bit, eliminate the fluid area at the bottom of the well, accelerate the upward flow of drilling cuttings and improve ROP.

2. High saturation NBR bearings can reduce sealing pressure and improve sealing reliability.

3. The G-Gauge protection improves the measuring ability and prolongs the service life of the bit.

4. Adding a row of teeth between the rear taper and the outflow to trim the borehole and protect the cone.

| Minimum Order Quantity | N/A |

| Price | |

| Packaging Details | Standard Export Delivery Package |

| Delivery Time | 7days |

| Payment Terms | T/T |

| Supply Ability | Based on Detailed Order |