| Condition | New | Color | black or Customized |

| Applicable Industries | Construction works , Energy & Mining, Tunneling | Diameter | 45MM-76MM |

| Video outgoing-inspection | Provided | Thread Type | R25,R28,R32,R38,T38,T45,T51 |

| Machinery Test Report | Provided | Key words | Coupling Sleeve |

| Brand Name | Jcdrill | Application | Mining / Quarrying / Tunneling/Blasting |

| Type | Drill Sleeve | Length | 150MM-235MM |

| Machine Type | Drilling Tool | Formation | Hard / Medium hard / Soft Rock Formation |

| Material | Carbide | Bridge type | Semi-bridge / Full-bridge |

| Processing Type | Forging | Raw Material | High quality alloy steel |

| Use | Mining |

Introduction

Description

Coupling sleeves are available with both half-bridge and full-bridge types, as well as adapter couplings.

Semi-bridge coupling, by far is the most popular, has a small non-threaded bridge in the centre. The drill rod cannot thread past the centre of the couplings, and the smaller diameter rods portions butt together in the centre bridge area of the coupling. Semi-bridge couplings are most suited to high torque machines. Most rope (R) and Trapezoidal (T) threaded couplings are semi-bridged.

Full bridge coupling has a great advantage that it positively eliminates the potential for the coupling to creep along the threaded joints. These couplings, are typically used in a Trapezoidal thread, in surface drilling application, have better uncoupling characteristics and tend to maintain tighter joints. Full-bridge couplings have less chance of jamming and are best suited to machines equipped with independent rotation.

Adapter couplings are used when changing from one thread type, or size, to another and are typically required only in special circumstances.

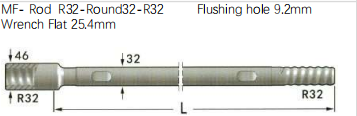

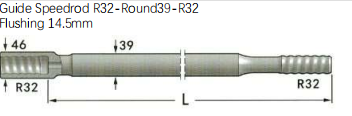

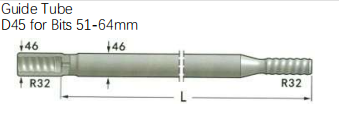

Crossover coupling using R32 thread system

• R32 thread system

• Widely used in drifting and tunneling

Color: Black or Based on Customer requirements

Material: Tungsten carbide and high strength alloy steel

Processing: CNC milling and proprietary heat treatment process

Type: R32 Crossover Coupling

Applications

• Underground Mining

• Tunneling

Competitive Advantage

High strength chromium-molybdenum steel with high fatigue strength and excellent wear resistance

Picture

| Minimum Order Quantity | N/A |

| Price | |

| Packaging Details | Standard Export Delivery Package |

| Delivery Time | 7days |

| Payment Terms | T/T |

| Supply Ability | Based on Detailed Order |